Pipette Materials

- Main Body, Counter wheels, Plunger Button = Special Grade Nylon 6/12 with reinforcing, lubricated additive.

- Hook and Top Cover = High impact, drop resistant Polyphenylsulphone

- Volume Display Window = High clarity, steam resistant Polysulfone

- Nozzle and Ejector Sleeve = Robust, chemically resistant Kynar

- Nozzle Filter = Porous Polyethylene with protective self-sealing additive

Don’t have time to read the post? Download the pdf version.

DOWNLOAD NOW

Life-Time Durability

Figure 1. Life Testing Apparatus

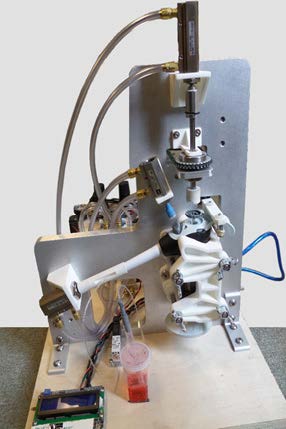

Method: A custom electro-pneumatic testing apparatus (Figure 1) was developed to simulate heavy pipette use; including mounting and ejecting of tips, aspirating and dispensing liquid, changing volumes, and adjusting the hook. Calibration scales as well as force and torque gauges were used to periodically measure the performance of an Ovation M 1000 mL pipette throughout the testing. Results: After ~1000 hours of extreme testing, including 1 x 106 tips, 1.5 x 106 aspirate and dispense cycles, 23 x 103 volume adjustments, and 6 x 103 hook adjustments, to simulate 5 years of extremely heavy use, the pipette continued to aspirate and dispense as accurately as the unused unit (Figure 2). Plunger and volume adjustment forces remained stable throughout and the hook did not become loose. Most importantly no leaks ever developed.

Figure 2. Accuracy drift over lifetime of 1000 mL Ovation M without recalibration

Structural Integrity

The Ovation M was designed to be fully autoclavable for convenient sterilization in the lab. Typically, repeated exposure to high temperature and pressure environments of a standard steam autoclave can structurally weaken most pipettes and alter their performance. Method: To determine the effects of autoclaving on the Ovation M, units were autoclaved 16 times for 20 minutes using steam sterilization at 121 oC/1 atm, followed by a 20 minute drying period at 121 oC, followed by a 30-60 minute cooling period outside of the autoclave. Calibration and functionality was tested after every 4th autoclave cycle at the low and high volumes.

Results

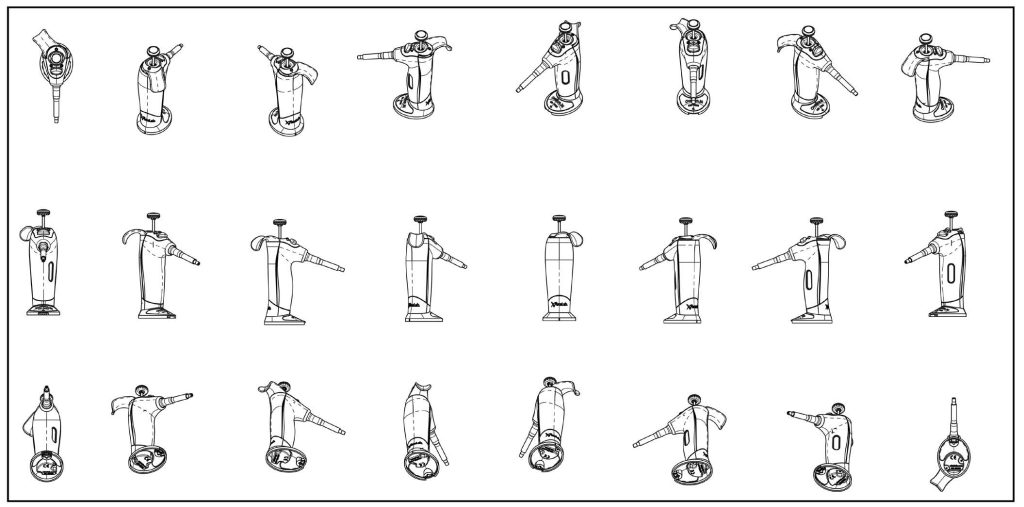

After verifying the post-autoclave calibration, structural integrity of the pipette was tested by repeatedly dropping from 48” (122 cm) onto a concrete floor. Each of the 24 drops was performed with a different pipette orientation at impact in order to try to capture as many outcomes as possible (Figure 3). After every drop, the unit was tested for leaks and full functionality.

Figure 3. Drop testing chart of 24 different pipette orientations

Conclusion